できることを、

できる限り。

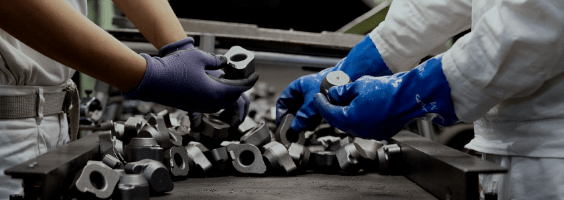

お客様のお困りごとに、精一杯お応えする。

どんなことでも「なんとかしよう」と全力を尽くす。

納期を遵守して、世界品質の製品をお届けする。

そうした姿勢を貫いてきた結果。

「マツバラにしかできない」

「マツバラならなんとかしてくれる」

といった評価や信頼をいただけるようになりました。

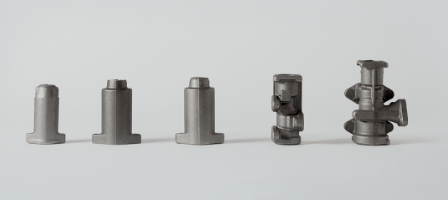

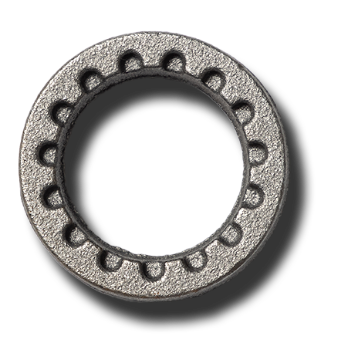

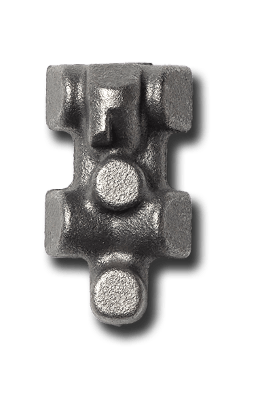

私達は小型鋳物の専業メーカーです。

小さな部品も。薄い部品も

一個の製造から対応いたします。

小物鋳物専業メーカーとして、

幅広い産業分野に製品を提供しています。

若い人材が多く、設備投資も積極的に行っています。

永く安定的に製品をご提供できる体制を整えています。